what needs to be done with the cement underlay flooring before adding new flooring

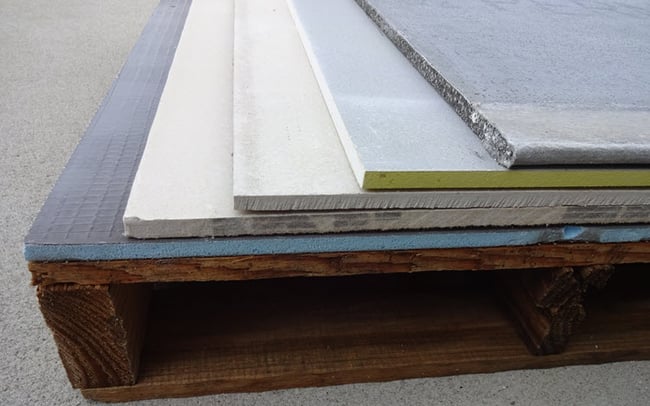

For a beautiful and long-lasting tile installation, yous need to ensure that every facet of the job is completed properly according to tile industry standards and best practices. The key element here is the foundation of the installation and that's where underlayment for tile solves a multitude of problems. Some Underlayment History What Constitutes an Underlayment for Tile? Iii Types of Tile Underlayment ane. Backer Board Underlayments 2. Floor Underlayments Preparation Materials iii. Membranes What's the Right Solution? Reader Q&A Last Note: Beware of Using Thin Ready to Cut Costs In the by, floor preparation materials were not as readily available as they are today. In those days, when an installer encountered an inappropriate subfloor, information technology was up to you - the installer - to discover a way to make the floor flat enough to install the large format tile of the twenty-four hours, the infamous 8x8, without one tile edge beingness higher than the side by side tile. The term "lippage" was rarely used if it even existed. Installers in those days needed to be creative in fixing low spots, peculiarly in a woods subfloor. Perhaps using multiple layers of plywood until the depression spot disappeared and 1 of the early generation floor patch products to fill in the remaining spaces. This was a time-consuming method and, many times, not that effective in creating a flat floor especially given theANSI Specification A108.02-4.1.four.3.1, Subfloor Surfaces: Today, for tiles with all edges shorter than 15 in. (0.38m), the maximum allowable variation is no more ¼ in. in 10 ft. (six mm in 3m) and no more than than one/16 in. in ane ft. (1.6 mm in 0.iii thousand) from the required aeroplane, when measured from the high points in the surface. For tiles with at least ane edge 15 in. (0.38m) or longer, the maximum allowable variation is no more than 1/eight in. in 10 ft. (3 mm in iii yard) and no more than 1/16 in. in 2 ft. (one.six mm in .six m) from the required aeroplane when measured from the loftier points in the surface. Getting the substrate to within these tolerances becomes a dilemma with today's large format tile sizes. How does an installer prepare the flooring, so it is flat plenty to receive tile? The solution is underlayment. Although there's no tile industry definition for the category of "underlayment," this group easily includes products such as: The product chosen depends on what problems are identified upon examining the subfloor or substrate of the installation. More specifically, If the flooring surface, be it woods or concrete, is not flattened or leveled to meet industry requirements and standards prior to starting the installation, chances are high that problems will exist encountered. Too, wall surfaces demand to be properly prepared to eliminate potential issues. The 6 underlayment products listed above fall into three categories: Knowing which ones piece of work appropriately is critical to the success or failure of the projection. Given the e'er-changing and fast-paced appearance of new products on the market place means that a tile installer or contractor must stay abreast of these new technologies. Permit's examine each category in plough. Capitalist lath, as a category, has been around since the 1970s. The development and mass-production of this product revolutionized the tile industry by providing a tile-prepare surface in the grade of a sheet or console for floors, walls, and ceilings. Some of the products in this category fall under an American National Standard Establish (ANSI) designation while others agree an American Society of Testing Materials (ASTM) characterization. The Tile Council of Due north America TCNA) Handbook includes the following as Backer Board: Every bit a full general rule on flooring applications, backer boards require a supporting layer of thin-set mortar or other production, every bit directed past the manufacturer. Furthermore, fastening the board and seam treatment should strictly follow the manufacturer's recommendations. Failure to do so can void the manufacturer'southward warranty. Realize that oftenthe floor area to be covered with backer lath will be irregular or wavy. The only viable way to correct this deficiency is to flatten the offending area with a trowel-practical patching product. This is extremely important since the patch needs to be nether the board, non on tiptop. That'south when the next categories of underlayment come into play. To obtain a floor or wall surface that is flat enough to receive tile, surface irregularities need to be corrected per the ANSI Specification A108.02-iv.i.4.three.1, Subfloor Surfaces detailed above. In order to run across or exceed these requirements, normally a troweled-on patch or self-leveling underlayment (SLU) is used. The National Tile Contractors Clan (NTCA) Reference Manual lists this topic every bit Underlayments, Trowelable, and Poured . Mortar beds were considered the grandfather of underlayments for solving many floor and wall irregularity problems. A mortar bed allowed the tile mechanic to correct the bug with a floor that was otherwise unacceptable or make a wall installation surface plumb and flat, eliminating lippage. Unfortunately, the mortar bed has lost some of its favor because a expert quality mortar bed takes time to produce, which jobsite schedules may non let. Mortar beds can also add pregnant weight to the structure, which may not be tolerated in today's tightly engineered buildings. Given the demands of fast-track projects and the get-it-washed-yesterday mentality of today's installations, mortar beds have go less prevalent. These changes take required the industry to make adjustments also. Somehow, manufacturers had to devise means to make the unacceptable floor acceptable for a thin-bed installation — and do it quickly. Hence, the newer products and methods detailed in this article. Floor patch materials come up from a variety of manufacturers and are used to obtain the required plane for tile installations. This includesfilling cracks, voids, rough surfaces, and low or depressed areas. Most of these products are latex-modified and require mixing with potable water.These patch products are designed to tenaciously bond to the properly prepared surface and fill low areas, also known as birdbaths, likewise as flatten out loftier spots. This entire exercise is the best way to "ready the flooring or wall." Trowelable underlayments contain cement, aggregate and are mixed with either beverage water or a latex additive. Many manufacturers recommend applying a slurry coat of the product to the substrate assuasive it to dry until information technology becomes tacky. The recommended liquid and powder mixture is so applied to the surface. Trowelable underlayment usually requires sanding after information technology dries to remove trowel ridges and allow for an additional layer if needed. Cocky-Leveling Underlayment, popularly known as SLU, is designed to flatten or maybe level a floor surface prior to installing tile. The floor surface must be properly prepared and primed with the manufacturer's recommended product and immune to dry. Many architectural plans and specifications require the floor to exist level. This is especially true for highly specialized medical and technical equipment that crave a perfectly level floor. In this instance, provide careful attention to detail when applying the SLU so that, when done, the bubble of a spirit level, light amplification by stimulated emission of radiation, or transit successfully indicates a truly level surface…. or not. 3 critical factors in an SLU project are: Also trivial h2o can impede the flow of the mixture while also much water can cause the aggregate to sink to the bottom, separating from the other components, yielding a weak and powdery surface. If the speed of the mixer is as well slow, the product will not be properly combined and may non function as specified. Conversely, if a drill that spins too fast is used to mix the SLU, information technology may begin to fix in the barrel. Be sure to take plenty help to mix, move, cascade, and smooth the product within the allotted time. In one case the SLU is poured onto the floor, move it into identify with a gauge rake having adjustable legs to control the production thickness. When completed, motility a surface smoothing tool across the surface to interruption surface tension and flatten the SLU. Allow the recommended dry time depending on the ecology weather before installing tile. Poured Underlayments usually fall into one of two categories: Poured self-leveling underlayments are composed of various grades of gypsum along with a number of chemicals that control the setting fourth dimension of the product and may be sanded or unsanded. Depending on the manufacturer'southward recommendations, they may exist mixed with beverage water or a latex admixture. If using a latex additive, it is always wise to use the product provided by the manufacturer. Many times, gypsum-based underlayments are used in conjunction with resilient flooring to patch small holes, cracks or to ramp up or down to an next floor finish. However, they may also exist used to flatten the large floor areas of properly prepared wood or concrete. Poured gypsum underlayments tin can solve subfloor issues such as out of flat and out of level, simply they need to be installed per the manufacturer's guidelines. In one case the underlayment has been placed by a certified poured gypsum installer, a drying fourth dimension of three to fourteen days, depending on the thickness must be observed. Additionally, the site temperature and humidity may be a factor in achieving an adequately dry installation. When the gypsum has stale to the manufacturer'southward specifications, the gypsum installer applies the required primer/sealer which prevents the gypsum from pulling the moisture out of the tile setting mortar. This premature moisture removal from the mortar tin compromise the bond of the tile to the gypsum. Pourable self-leveling underlayments (SLU) incorporate cement, aggregate and chemical additives which enhance their flowability and strength. They are mixed with either drinkable water or a manufacturer-recommended latex additive. Substrates are almost ever treated with a latex primer which serves two functions. The first is to increase the bail forcefulness betwixt the substrate and the SLU. The 2nd is to prime number the substrate which equalizes the assimilation rate of the substrate, thus eliminating hot spots which can prematurely dry out out the underlayment earlier it completes its designed curing process. SLUs assist in correcting out of flat and out of level subfloors and can be installed from as thin as i/16" up to 6" with compressive strengths ranging from three,500 to over seven,000 psi depending on the manufacturer. All of these applications require that the pattern load of the structure see the deflection requirement of 50/360. Once placed, SLUs ordinarily require between two and twenty-four hours to dry out before the tile can be installed. This timeframe will vary based on the thickness of the cement forth with the site temperature and humidity. Unremarkably, very minimal prep piece of work is required prior to the installation of the tile. One of the newest entries to the market has been Gauged Porcelain Tile and Gauged Porcelain Tile Panels/Slabs which until recently was known as thin porcelain tile (TPT). The installation of this product allows the installer only ane endeavour to set it correctly since it is almost impossible to slide or lift it once it has been placed into fresh mortar. Here the requirement for a flat substrate, both wall and floor, is critical. The ANSI standard for this product (A137.3) and its installation (A108.19) was adopted in April of 2017 wherethe substrate tolerances need to come across at least the 1/8" in 10' standard for tiles with at least one edge 15" (0.38 m) or longer every bit noted in ANSI A08.02-four.1.4.3.1. Information technology is imperative that the air is expelled or burped out from under the tile and that the trowel ridges are complanate. This lets little or no allowance for high or low spots in the surface to which the GPT is being applied. It must be corrected before the tile is installed. Waterproof membranes, befitting to ANSI A118.ten, are available in canvas and liquid forms and can be used with both vertical and horizontal sparse-bed and thick bed installations of tile. Some of these products have integral reinforcing fabrics for tensile force and minor crack-bridging properties. Cleft isolation membranes, conforming to ANSI A118.12, for thin-bed ceramic, glass, and rock installations act to isolate the tile from minor in-aeroplane substrate cracking. These products must exist load-bearing and bonded to the substrate in order to office properly. In some cases, the trowel-applied products tin can exist used as the agglutinative for the tile. Other products within the telescopic of this category are allowed to cure or are practical every bit sheet goods and are then used as the substrate for the tile. Uncoupling membranes are generally a plastic product that has some sort of bonding scrim or mesh applied to the back of the production to let it to be bonded to the wood or concrete floor. The face of the product may accept a geometrical configuration or a mesh to promote bond to the back of the tile and provide air infinite between the tile and the substrate to allow independent motion between the two and limit the transfer of stresses. Once in place, their function is to disconnect the tile surface from the substrate to help eliminate croaky tile. Uncoupling membranes may also act every bit a waterproofing membrane and function well in equalizing vapor pressure level weather condition encountered in young or newly placed physical. These membranes are non characterized by ANSI or ISO standards but must accomplish 50 psi or greater shear bond strength in seven days per the test method in ANSI A118.12 Section 5.1.3. Consult the manufacturer's written literature for specific installation details. Bonded sound reduction membranes, befitting to ANSI A118.13, are intended to reduce the floor-to-floor impact insulation grade (IIC) audio. These membranes may exist trowel applied, sheet, or composite materials that are bonded to a suitable substrate so that tile can be bonded direct to the membrane. The interesting matter about the products described hither is they may need to be used in concert with each other to provide a suitable surface for a quality tile installation. The floor may need to be flattened with a patch or SLU anywhere from just a skim-coat to as heavy every bit six inches. The surface may further need the advantages offered by a capitalist board or one of the membranes mentioned in a higher place. Underlayments do a great job thanks to manufacturers committed to innovative products that make the finished tile installation expect the way it should – flat and lippage-gratis. Whatever the case, always follow the manufacturer's guidelines and when possible, use products produced by a unmarried manufacturer. These two prerequisites along with using qualified labor, installers who meet the requirements of a Ceramic Tile Instruction Foundation Certified Tile Installer or Journeyman from the IUBAC, will heighten consumer confidence and ensure a cute and long-lasting tile installation. Anybody wins! >> Meet The Tile Installation Experience with Scott Carothers at Coverings Since publishing this article in June 2017, we've received the post-obit questions that Scott answers: Timothy Biltz asks: Have you heard about using CORK as an underlayment for ceramic tile? People are selling it for ceramic tile installations and it goes against everything I take learned over the terminal 31 years. Can y'all bring me up to speed? Scott responds: At that place is only i method using cork as an underlayment for the installation of tile in the TCNA Handbook. Method F135 is installed over on-basis or above-footing concrete using a very specific cork which must exist ½" thick (+/-.010") consisting of a mix of pure cork granules combined with a polyurethane binder, having a density of between 11.8 and 13.six pounds per cubic foot. The cork must be bonded to the substrate with an A136.1 organic adhesive and grouted with an A118.3 epoxy. Angus Mac asks: We are renovating the bath at home and doing the sheeting for the waterproofing and tiles myself. For the floor, I have tile underlay that all needs to slope i way to a slot bleed in the shower. The existing floor is timber. To achieve this gradient I accept put 10mm packers spaced 100mm apart at the high end and gradually reduced the packers to 3mm. Practise you have a better way of achieving this slope or will this be fine? Thanks Scott explains: The building codes in the United States, IRC for residential and the IBC for commercial installations, do not let for the structural framing to exist altered in society to facilitate the gradient required in a shower application. This ways that any gradient provided must be on height of the framing and must accept ¼" per foot slope to the drain. If the installation will allow for additional height, a mortar bed could be used or past using a manufacturer-provided panel. For boosted data, please refer toDoes Your Tile Slope To the Drain? Karl Seggerman asks, I want to lay tile over a plywood subfloor in my kitchen/living room. The floor is structurally sound with trusses on 12" centers beneath. Want to be able to have a piano, entertainment center, kitchen table, couch, and china cabinet sit down on and be moved around on this flooring with advisable protection/sliders. What is my all-time pick for underlayment? I want to make certain it is best for the load of the furniture. I presume it should likewise take some waterproofing qualities because of the kitchen. Scott responds: Before any tile installation begins, the ability of the structure to carry the additional weight (of the tile assembly) must be determined. Nearly times, enlisting the expertise of a structural engineer or architect would be a wise choice. If the structure is adequate, the underlayment should be a part of his or her recommendation. Although not required, a waterproofing organisation is a good choice someday h2o is nowadays. Additionally, be certain to include expansion joints around the perimeter and throughout the installation equally detailed in the TCNA Handbook section, EJ171. >> See Why Do You Need Expansion Joints When Installing Tile? Seth Diamand asks, Scott, I'g faced with a height upshot I am not sure how to proceed with. I am a homeowner who is going to be tiling nigh 60 sq. ft. in ane end of a family unit room. The room was converted from a garage long earlier we bought the house. We tore up the carpeting and pad to discover 3/4" tongue and groove plywood. I'm non sure how large the floor joists are, only the nailing pattern suggests a little less than 16" on center. Nosotros had three/4" thick white oak hardwood installed directly on the subfloor with no additional underlayment, only a vapor barrier. I now need to match the height of the flooring, and so the tile installation volition be affluent with the floor. I was planning on adding a iii/8" layer of plywood and applying thin-set direct to the plywood and then the tile (5/16" 12x12 glazed porcelain) to be as close to the floor acme as possible. It seems like a 1/4" CBU will exist too thin. I was too going to back butter the tile as well as added insurance. What is the best way to solve this issue? Thanks in advance for your help. Seth Scott says, Equally mentioned in the above question, determining the power of the structure to bear the additional weight of the tile assembly is disquisitional. The design professional should brand specific recommendations for vapor retarding membrane, crawl space ventilation, which TCNA Handbook method would exist best suited for your installation. Be sure to include the required expansion joints equally detailed in the Handbook section EJ171. Gary Elsner asks, Howdy Scott, I've got a question. I accept a habitation in Naples FL. I'k having my physical tile roof replaced. It was suggested that my contractor use TU Plus, a Polyglass Q product. My contractor claims they are back-ordered on that and is going to use Polystick MTS, also a Polyglass product as the underlayment. He claims they are interchangeable and only as good a product. Would y'all hold with that assessment? I've gone to their website and they seem to be equal, just I'thousand interested in what you lot accept to say about it. Thanks in advance, Gary Elsner Scott explains, Physical tiles for a roof are not a part of the ceramic or porcelain tile standards and methods. It would be best to go a recommendation (in writing) from the manufacturer of the available production as to its suitability and warranty before proceeding. Gregg Moore asks, Scott, I have a commercial projection in a celebrated building in Washington, DC. The current flooring (hardwood) has been removed and new ¾" plywood has been installed, with the total subflooring beingness ¾". I'm recommending installing an additional 1/ii" cement backer board over the plywood prior to the 12" X 24" porcelain flooring tile. Is that a good method? The architect is recommending a i/4" cement backer board. Cheers, Gregg Moore. Scott's response: Every bit the pattern professional, the architect would exist the person to design an installation arrangement advisable for the celebrated structure. Whether the capitalist board thickness is ¼" or ½" would be up to the combined expertise of the architect and the backer lath company. To be certain everyone is on the aforementioned page, become the recommendation in writing. Jenny Ewasiuk asks, My husband and I are installing a 13"x13" x 3/viii" tile. Nosotros accept a 3/4" transition to deal with and want to proceed it continuous tile. Nosotros want to make a nice gradual transition of most five" wide fabricated out of tile to connect the two areas (hallway into a reading room). We thought we could support the tile with an angle-cut piece of plywood underneath. How do we brand a nice transition that won't hurt bare feet? We're worried cutting the tile at an bending volition give it a precipitous border. Any suggestions? Thanks for your time. Scott says: A tapered piece of plywood may be difficult to fabricate and may not offer the support required for a practiced installation. If the construction is adequate, the apply of a cement-based floor patch that allows for the needed height may be the all-time pick. Once properly in place and cured, the tile tin can exist installed. At the two angles, specially the one at the high bespeak, ease the cut edge with a rub stone to eliminate whatever sharp edges. Also, at this intersection, information technology would be wise to fill up one or both of these joints with a C920 sealant such equally 100% silicone or urethane. Tim Briggs asks, Built in 2015. I used TGIs 16 inch on center with Menards three/4-inch exterior waterproof 5 ply plywood equally my subfloor. Afterward nailing it down every half dozen inches apart with PL 400 construction adhesive, I let it gear up for nearly 6 months before the tile installation. My tile setter used a i/8-inch 5-notched trowel placing the thin-set before screwing down 1/4-inch Dura Rock. He then used a 1/4-inch notched trowel placing the thin-set before installing the 12 10 24-inch tiles. Within i year afterwards the installation, many of my tiles have broken, grout lines have cracked with the grout coming out, and many tiles coming loose. Do y'all have any suggestions for me? I am going to remove all tile, remove the dura rock and re-spiral the subfloor next spring and get-go over. Scott's response: I probably sound like a broken record, but was the flooring system designed to behave the weight of a tile assembly? The issues you outlined are either the result of movement in the structure, the lack of movement accommodation (expansion) joints, or both. If the construction is non properly rated, you will need a structural engineer to assist in a remedial plan. If the construction is adequate, meeting the required 50/360 deflection specification, it is time to first again. However, at that place are several questions that must be answered before commencing any piece of work: You lot mentioned the use of a i/8" notched trowel for the mortar under the backer board. This is not sufficient and should follow the manufacturer's recommendations. I wish you well on the replacement. Kevin Schlosser asks, I really found your article informative. I accept a customer coming up presently that wishes to utilise a thin-set with a wire mesh over a subfloor that has had carpet removed. To the all-time of my knowledge, this is an archaic method. She says information technology'south the but way she wants it done. What would you tell her and what are your recommendations to provide a proper substrate in this moldy carpeted bathroom? I was going to put downward kilz primer and practise a cement backer board. Cheers so much for the response! -Kevin Scott'south response: First off, if mold is a part of this scenario, someone needs to hire a mold remediation adept and eliminate the trouble. These folks are trained and insured to handle mold properly. The but TCNA particular that includes wire mesh would be F145 which includes expanded metal board with a minimum weight of two.5#/square grand installed over a cleavage membrane and a mortar bed thickness of 3/4" minimum to ane-1/2" maximum. Realize that this will enhance the level of the flooring which may not be acceptable at a transition. Sometimes when the consumer dictates the installation method to be used on the chore to the installation expert, the best course of action would be to walk away. Cheers for your questions! A final note. Unfortunately, some not-then-well-trained or poorly informed tile placers (not tile mechanics or installers) mistakenly believe that whatever is in the back of the truck or leftover from the terminal job is appropriate to patch the low or high spots. This is entirely wrong! Thin-set or even the newly designated large and heavy tile (LHT) mortars are non designed to repair these surface irregularities. Consumers should be wary of contractors who say that underlayment products are not needed and add together unnecessary costs to the project. >> SeeLooking to Hire a Tile Installer? Here's Your Roadmap. Watch out for this one… Information technology'due south a recipe for failure from the showtime. The least expensive price for the job may be the nearly expensive in the long run. Thank you for reading. Note: This article was originally published on June 6, 2017, and has been updated.

Tile Underlayment Guide Table of Contents

Some Underlayment History

What Constitutes an Underlayment for Tile?

Three Types of Underlayment for Tile

i. Backer Board Underlayments

ii. Floor Underlayment Preparation Materials

Mortar beds

Troweled-On Floor Patch

Trowelable Underlayment

Cocky-Leveling Underlayment

1. Accurately mensurate the water for the mix.

two. Use a mixer that maintains the proper speed.

3. Mix for the recommended time.

1. Gypsum-Based Underlayments

All of these applications require that the design load of the structure come across the deflection requirement of L/360.

2. Cement-Based Underlayments

Critical Note: Gauged Porcelain Tile and Gauged Porcelain Panels/Slabs normally known as GPT require a apartment substrate.

3. Membranes

Waterproof Membranes

Crack Isolation Membranes

Uncoupling Membranes

Bonded Sound Reduction Membranes

What'southward the Correct Solution?

Reader Q&A About Underlayments

Cork Underlayment for Tile?

Achieving a Slope in a Shower

Underlayments and Furniture Loads

How to Match Floor Heights?

Underlayments and Concrete Tile Roofs

½" or ¼" Cement Backer Lath Under Porcelain Tile?

How to Deal with Transitions From 1 Tiled Flooring to Another?

Why Are My Tiles Breaking, Coming Loose, and the Grout Slap-up and Coming Out?

How to Respond to a Customer Requesting Thin Ready with a Wire Mesh Over a SubFloor?

Final Note: Beware of Using Sparse Set to Cut Costs!

Scott

Source: https://www.ceramictilefoundation.org/blog/ultimate-guide-to-underlayment-for-tile

0 Response to "what needs to be done with the cement underlay flooring before adding new flooring"

Enviar um comentário